“The 2025 Tesla Model Y refresh, codenamed Juniper, has sparked discussions about its safety and structural integrity. While its exterior and interior updates are subtle, the real story lies beneath the surface.”

In this detailed teardown, we examine the vehicle’s critical components—from bumper beams to thermal systems—to evaluate how Tesla balances innovation, safety, and cost efficiency.

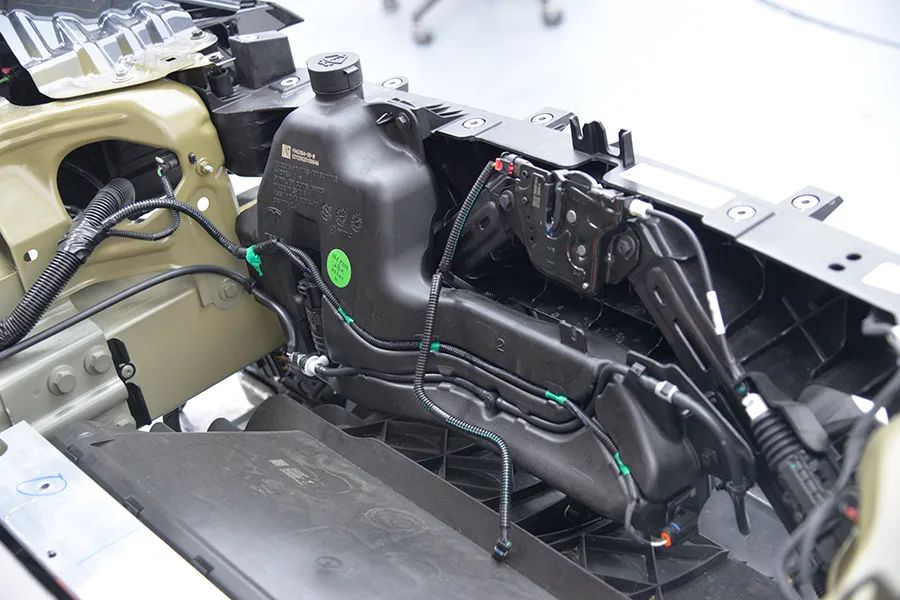

1. Front Compartment: Materials and Thermal Management

1.1 Aluminum Body Panels

The refreshed Model Y retains aluminum hoods, doors, and tailgates, while other body panels use stamped steel. This mix optimizes weight reduction and structural rigidity. Notably, the front compartment’s clean layout highlights Tesla’s advanced thermal management system, which maximizes space for the frunk (front trunk).

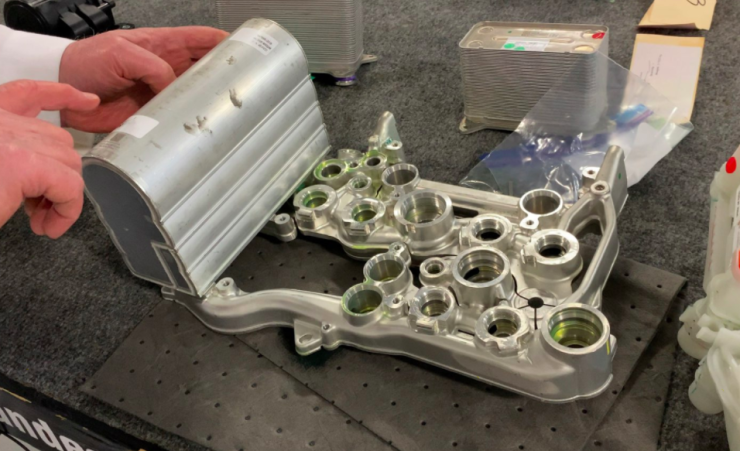

1.2 Thermal System: “Super Manifold”

At the heart of Tesla’s thermal management is the Super Manifold, a control valve that consolidates all heat exchange pipelines. This system efficiently distributes heat to optimize battery performance and range—a technology widely emulated by competitors.

1.3 Safety Features for Emergency Response

A high-voltage interlock circuit is integrated to ensure rescue safety. In severe accidents, firefighters must cut this circuit to de-energize the vehicle before extraction—a feature still rare in many EVs.

2. Front Bumper Beam: Design and Safety

2.1 Aluminum Construction

The front bumper beam remains aluminum but is slightly thinner (4.02 mm vs. previous models), reducing weight without compromising coverage (82.98% of the front width). Its “日”-shaped cross-section enhances energy absorption during collisions.

2.2 Collision Deflection Mechanism

Two 25% offset collision guide blocks are installed at the beam’s ends. These deform during impact to redirect force away from the A-pillar, protecting the cabin—a design validated by Tesla’s top NHTSA safety ratings.

2.3 Pedestrian Protection

A new active hood system uses air pressure tubes and sensors in the foam layer. When a collision with a pedestrian is detected, the hood pops up to reduce injury severity—an upgrade absent in older models.

2.4 Cost-Cutting Adjustments

The secondary bumper beam, previously aluminum, is now plastic. Additionally, radar systems (ultrasonic and millimeter-wave) have been removed, relying solely on Tesla’s camera-based Autopilot.

3. Rear Bumper Beam: Simplified Yet Effective

3.1 Aluminum Beam with Reduced Thickness

The rear beam is also thinner (4.05 mm) but maintains aluminum construction. Its coverage (64.71% of the rear width) and non-protruding design prioritize aerodynamics over rear-impact protection—a trade-off noted in crash tests.

3.2 Absorber Box and Bolt Configuration

The rear absorber box features three bolts, unchanged from prior models. While simpler, this design still meets global safety standards, as seen in Tesla’s consistent 5-star NHTSA ratings.

4. Structural Safety and Crash Performance

4.1 Unchanged Safety Cell

Despite thinner bumper beams, the Model Y’s passenger cell remains robust, using high-strength steel and aluminum to channel crash forces away from occupants. This aligns with Tesla’s “crumple zone” philosophy, which has earned it accolades for rollover resistance (7.9% risk, the lowest among SUVs).

4.2 Global Crash Test Data

The 2025 Model Y has not undergone new IIHS or Euro NCAP tests, but its structural similarity to previous models suggests comparable performance. Most overseas Tesla models are exported from China, and their safety records remain strong.

5. Cost Optimization: A Double-Edged Sword?

Tesla’s cost-saving measures are evident:

- Thinner aluminum components reduce weight and material costs.

- Plastic secondary beams and removed radar systems streamline production.

- Simplified cooling vents and a smaller radiator opening (with active shutters) improve aerodynamics.

However, these changes haven’t compromised core safety metrics, as the vehicle’s fundamental architecture—including its gigacastings and battery shield—remains intact.

6. Conclusion: Balancing Innovation and Affordability

The 2025 Tesla Model Y refresh exemplifies Tesla’s strategy: refining proven designs while trimming costs. Key takeaways include:

- Safety-first engineering with advanced crumple zones and pedestrian protection.

- Efficiency gains via thermal management and aerodynamic tweaks.

- Cost reductions that maintain compliance with global safety benchmarks.

For EV enthusiasts, the Model Y continues to set standards in safety and innovation. However, competitors are closing the gap, particularly in radar-based driver aids and material quality.

Stay tuned for our upcoming analysis of the Model Y’s battery and chassis!